Toby got the ZeroOne oil catch tank powdercoated wrinkle black to match the intercooler piping. No more ricey logo :)

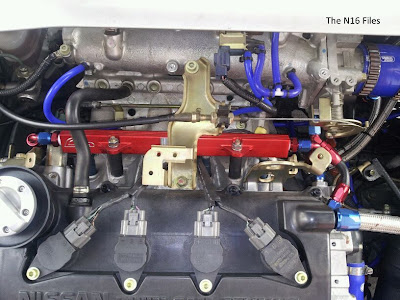

My AEM water/methanol injection filter has been installed.

Close up of the installed filter.

Turbosmart mechanical fuel pressure regulator gauge installed. Allows for easy troubleshooting should the fpr fail (touch wood) like what happened with the Tomei. I might have an electronic sensor and associated wiring installed in the future so my dash can display fuel pressure.

I replaced the bonnet switch as the rubber covering was torn and had come apart.

Picture of the new switch.

Install is simple DIY as the switch is secured via a Phillips bolt underneath the rubber cover.

The stock top radiator brackets were previously re-drilled to move the radiator further forward in the engine bay for more room with the stock cooling fans. Big mild steel washers were used to try and cover up the unused stock hole. Very unsightly (to me).

Moving the radiator further forward was also creating a problem as the front edge of the radiator cap would occasionally come into contact with the underside of the bonnet during engine movement. I did not measure the height of the Mishimoto and stock radiator but suspect the Mishi could be very slightly taller in height when compared to the stock radiator. Also suspect with the smaller profile of the Mishi radiator cap this might not be a problem but then again I don't dig the Mishi radiator cap.

With the SPAL fans giving more clearance this is no longer required so I took the opportunity to purchase a pair of new top radiator brackets from TCEAS. Cost me RM90+ for a pair after a measly 5% discount.

Left hand side (passenger) bracket installed. Used black anodized fasteners this time. Looks more sinister. Will not try my Cosworth radiator cap till I am absolutely sure there are no contact issues.

Also took the opportunity to replace the stock rubber coolant overflow hose with a bling blue Samco silicone item. Will do my windscreen wiper nozzle hoses when time permits. Need to look at heat shielding for the alternator.

Speaking of blue here's the only blue bolt in my engine bay. Blue for air mah! Where's the MAF sensor?

My bottom intercooler piping is very close to both the radiator and front lower engine mount with the occasional contact. No amount of adjustment is going to resolve this issue so I will just soldier on for the time being with a redesign/mod of the bottom intercooler piping on a list of things to upgrade for the future. This list is getting longer by the week. Sigh.. With the lower intercooler piping of for inspection I took the opportunity to wrap it with the unused downpipe wrap from my Design Engineering (DEI) Titanium Turbo Shield turbo blanket. I will try the DEI Reflect-A-Gold in the future in place of the downpipe wrap.